Performance

up to 5500 pcs/hour

up to 5500 pcs/hour

Weight measurement accuracy

±15 g

Options:

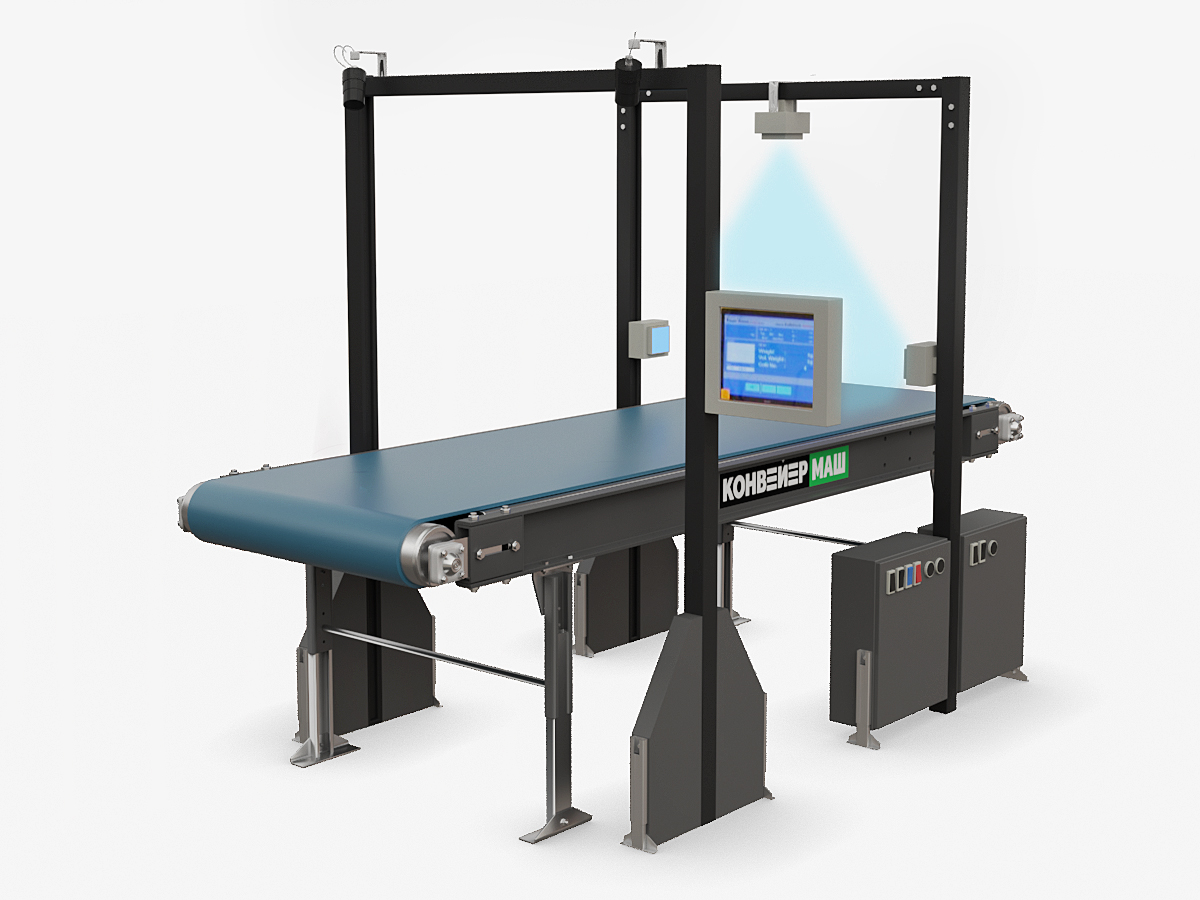

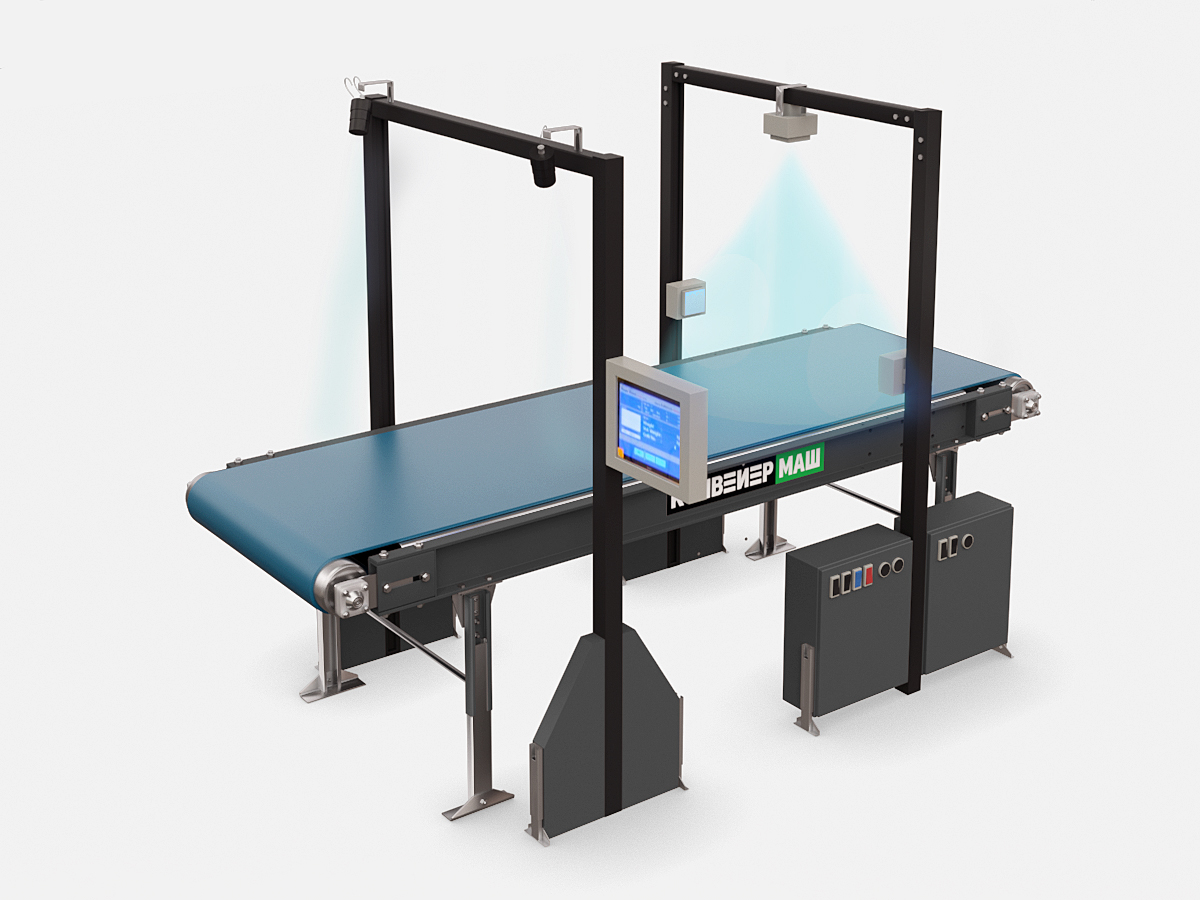

- Automatic barcode scanner

- Photo fixation of goods from 2 sides

- Rejection according to the conditions

Managing information about the weight and dimensions of goods received and shipped allows you to influence the cost of operations and the efficiency of the warehouse

We produce equipment for automating the processes of measuring weight and dimensions, which will automatically receive this data.

We integrate the equipment into your DWS, provide service and technical support.

Dynamic scales are certified by VNIIMS (All-Russian Scientific Research Institute of Metrological Service)

Automated measurement of cargo dimensions makes it possible to speed up the process several times compared to manual operations and eliminates the human factor, which leads to numerous typos and errors.

These systems can be used as part of conveyor lines or separately to quickly obtain dimensional data when shipping or receiving goods.

They are usually used together with weight conveyors to obtain full weight and dimensional characteristics.

Our HGH measurement stations are used for:

- AUTOMATIC REGISTRATION OF HGH IN THE ACCEPTANCE AREA

- OPTIMIZING THE USE OF STORAGE SPACE

- OPTIMIZATION OF TRANSPORT LOADING

- CONTROL OF THE CORRECTNESS OF THE ORDER ASSEMBLY IN THE SHIPPING AREA

- CHECKING THE CORRECTNESS OF THE INVOICES FOR TRANSPORTATION